Sheet Metal Roofing

Overview

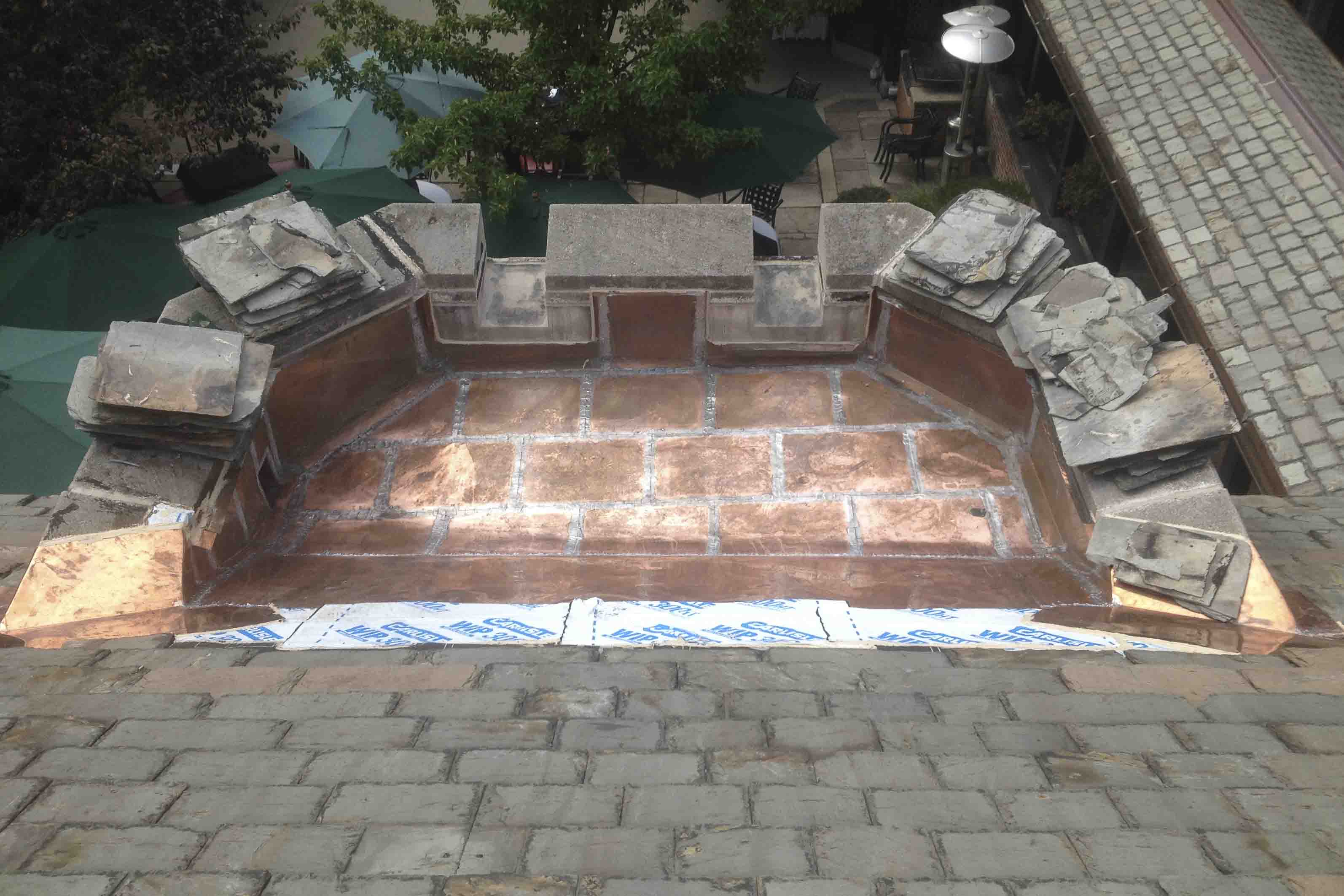

- The creative use of metal in roofing can yield highly artistic results

- Copper, zinc and stainless can be utilized to dramatic effect as demonstrated at:

- Richardson Olmsted Complex

- Our Lady of Victory National Shrine & Basilica

- Painted steel and aluminum shingles or panels can:

- Make an ordinary building stand out dramatically

- Provide durability that lasts several decades

Sheet metal roofing

Require very little maintenance, provide extreme weather protection and typically last up to 50 years

Sheet metal flashings

We fabricate all of our own flashings, which speeds up installation and allows for flexible, custom design

Custom specialties

From finials, louvers, weather vanes and lamps to other specialized creations, our skilled craftspeople are known for their artistry

Old meets new in our full-service sheet metal shop

Our state-of-the-art computerized brake and shear equipment sits aside a hand beading machine and stake bench. We have the capacity to create miles of standard aluminum or steel flashings, as well as the artisan workmanship to craft:

- Custom gutters

- Steeples

- Weather vanes

- Sconces

- And more

Sheet metal roofing

50 years of protection against the elements

A durable, low-maintenance option, metal roofing systems help provide superior resistance against extreme weather conditions. Typically lasting up to 50 years, metal roofs are highly reliable and becoming increasingly more popular in the industry.

Proper installation is critical to the longevity of your metal roof. Grove Roofing’s highly qualified installers pay close attention to detailed installation of the flashings while also selecting the proper underlayment.

Standing seam

- The most common sheet metal roofing option

- 12–24” wide vertical panels run from eave to ridge

- Adjacent panels are locked together in a variety of seam types

- They typically snap lock or use a mechanical seamer

- Materials:

- Painted steel and aluminum are the most common

- Copper, zinc and stainless steel are also good options

Batten seam

- Originally made from vertical leg panels inserted between wood batten strips and capped

- Now they are often made entirely of metal

- Designed to shed water, they’re largely used in architectural applications

- Available in aluminum, copper, zinc and stainless

Flat-lock seam

- Typically used on flat or low-pitch roofs

- Also used for curved surfaces, such as domes and barrel vaults

- Individual panels are interlocked together and joints are typically soldered

- Copper is the most common material

Sheet metal flashings

Custom-fabricated flashings reap many benefits

At Grove Roofing, we have the technology, resources and know-how to fabricate all of our own flashings.

Benefits to customers include:

- Flexible, custom design that field conditions typically necessitate

- A faster, more efficient installation process

- Eliminating the backlog of external fabricators and shipping time

Our sheet metal flashings capabilities include:

- Coping

- Fascia

- Gutters

- Downspouts

- Through-wall

- And more

Protect the perimeter with metal flashings

The perimeter is typically the most vulnerable part of a roof system. Metal flashings are critical in acting as a rain and wind shield, providing the necessary rigidity to terminate the roof membrane, and facilitating water leaving or aggregate staying on the roof.

Metal flashings also shield exposed joints in underlying membrane flashings as well as add durability and redundancy at penetrations for venting or drainage.

Custom specialties

The sky’s the limit with custom specialties

Many of our experienced technicians have perfected their talents to the level of artistry, producing finials, louvers, weather vanes, lamps and other specialized creations. They have considerable experience working with copper as well as aluminum, steel, lead and zinc.

Grove Roofing’s custom specialties include, but are not limited to:

- Clock towers

- Lamps

- Weather vanes

- Half-round or built-in gutters

- Ornate conductors

- Downspout leaders

- And more!

Copper components can last over 100 years

- The properties of copper make it unique among the metals that are commonly used in construction. For example:

- Extremely durable, it can last over 100 years as a roof system component

- It’s malleable enough to be formed to almost any curves or shape

- It can also be soldered or welded to form continuous lengths

- The oxidation of its finish transforms from golden bronze to a beautiful grey-green

Our trusted manufacturers

Ask us about the breadth + depth of our cutting-edge technology

Commercial roof repair and maintenance for buildings of any size.

716.828.1870

info@groveroofing.com

© 2023 Grove Roofing Services Inc. All rights reserved.